Anwendungen

- Radon & Thoron

- Radon-/Thoron-Folgeprodukte

- Radioaktive Aerosole, Air Sampling

- Radioaktive Kontamination, Quellensuche

Bodenluftmessung bezüglich des Radon-Risikos bei Bauvorhaben

Bodenluftmessungen dienen der Abschätzung der Radonverfügbarkeit im Boden als häufigste Ursache für erhöhte Konzentrationen in zu errichtenden Gebäuden. Anhand dieser Analyse können geeignete Präventionsmaßnahmen bereits vor Baubeginn getroffen werden.

mehr erfahren

Geologische Untersuchungen, Vulkanismus- und Erdbebenforschung

Aufgrund seiner Eigenschaften als inertes Edelgas stellt Radon einen der wichtigsten Geo-Tracer dar. Im Bereich tektonischer Verwerfungen oder geologischer Anomalien wird dabei Radon im Boden oder an Austrittsstellen gemessen. Veränderungen der Konzentrationen deuten auf tiefer in der Erdkruste stattfindende Veränderungen hin.

mehr erfahren

Lüftungssteuerung zur Einhaltung des gesetzlichen Referenzwertes

Eine effiziente und preiswerte Maßnahme zur Reduzierung der Radonkonzentration in Bestandsgebäuden ist die gezielte Lüftung von Räumen.

mehr erfahren

Bewertung der Radonsituation an Arbeitsplätzen und in Wohnräumen gemäß StrSchG

Seit 31.12.2018 gilt die novellierte Strahlenschutzverordnung. In durch den Gesetzgeber definierten Verdachtsgebieten müssen Arbeitgeber und Wohnungsvermieter nachweisen, dass der jährliche Mittelwert der Radonkonzentration 300 Bq/m³ nicht überschreitet.

mehr erfahren

Radon Online Überwachung in Gebäuden und Anlagen

In größeren Gebäuden oder Anlagen besteht oftmals die Notwendigkeit, die Radonkonzentration verschiedener Räume oder Bereiche zentral zu überwachen. Die Einhaltung oder Überschreitung von Grenzwerten soll durch eine Großanzeige für Mitarbeiter oder Arbeitsschutzbeauftragte sichtbar gemacht werden.

mehr erfahren

Radon-Personendosimetrie

Ursache für die schädliche Wirkung von Radon ist die Akkumulation der Radonfolgeprodukte im menschlichen Atmungstrakt. Das heißt, nicht das Radon selbst, sondern die in der Atemluft generierten Zerfallsprodukte bestimmen die Dosis.

mehr erfahren

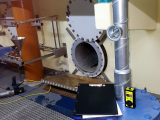

Schutz vor hohen Radonkonzentrationen im Bergbau, Tunnelbau und in Wasserwerken

In nicht dauerhaft belüfteten Räumen können sich sehr hohe Radonkonzentrationen aufbauen. Typische Beispiele dafür sind Stollensysteme im Altbergbau oder Hochbehälter in Wasserwerken. Diese werden zyklisch zu Sanierungs- oder Reinigungsarbeiten begangen.

mehr erfahren

Suche nach Radon-Eintritts- und Ausbreitungspfaden in Gebäuden

Zur Reduzierung erhöhter Radonkonzentrationen in Bestandsgebäuden ist die Kenntnis über die Quelle und die Ausbreitungsmechanismen im Gebäude von fundamentaler Bedeutung. In den meisten Fällen gelangt Radon aus dem Boden unter dem Fundament in das Gebäude aber auch uranhaltige Baumaterialien kommen als Ursache in Frage.

mehr erfahrenHäufig gestellte Fragen

- Worauf achten bei der Geräteauswahl?

- Welches Gerät liefert das schnellste Messergebnis?

- Welches Messgerät passt zu meiner erwarteten Radonkonzentration?

- Was bedeutet Langzeitkontamination?

- Was bedeutet Sensitivität? Ist sie wichtig?

- Ist Thoron ein Thema, das mich auch betrifft?

- Welches ist der Vorteil bei zeitaufgelöster Radonmessung?

- Wie genau kann ich Radon messen?

alle anzeigen

SARAD GmbH

Wiesbadener Straße 10

DE-01159 Dresden

Telefon: +49 351 65807-22

Fax: +49 351 65807-18

E-Mail: info@sarad.de

Alle Neuigkeiten per E-Mail